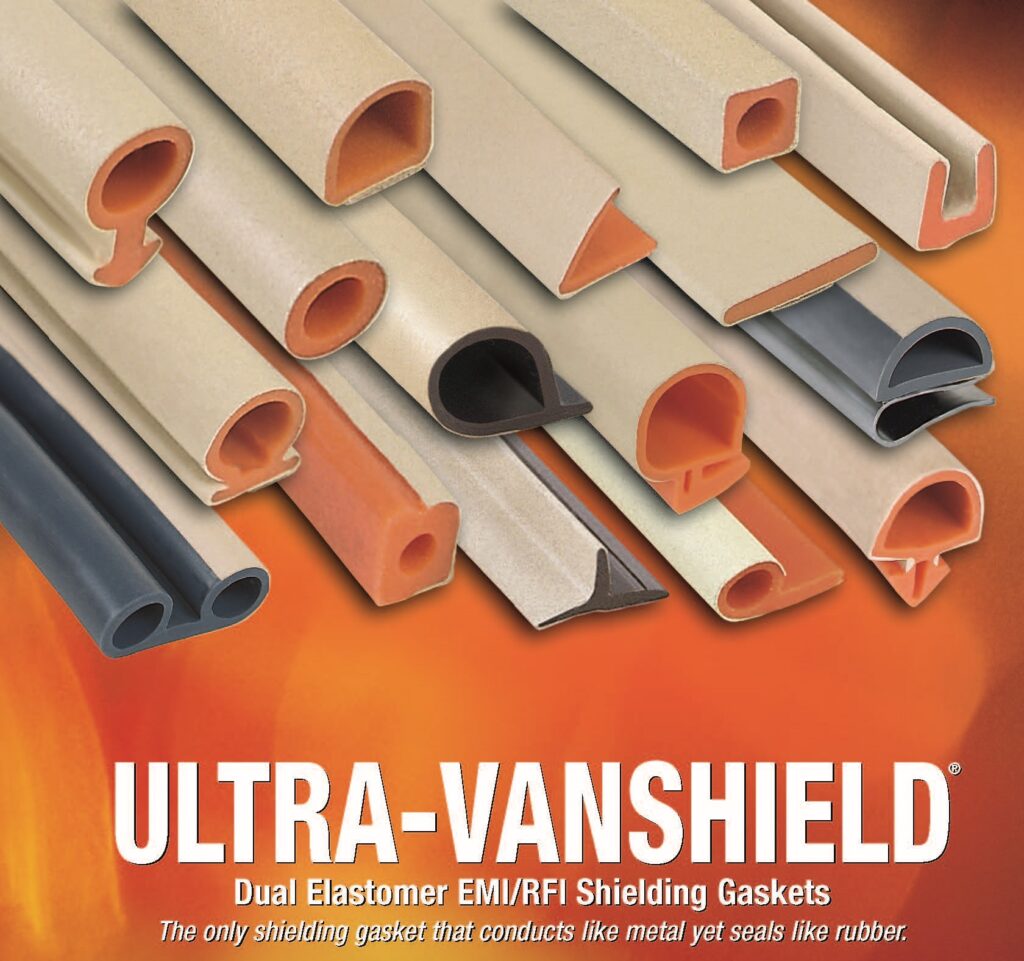

Vanguard Products Corporation provides customers across the globe with reliable EMI/RFI shielding and conductive gaskets to protect sensitive electronic equipment. With the goal of addressing your specific needs, we supply custom solutions in different sizes and materials, with cross-sections measuring 0.010″ to 3″.

We pride ourselves on offering EMI shielding gaskets with the highest possible EMI shielding, environmental sealing, and mechanical properties. Flame retardant options that meet UL94V0 requirements with low compression force are also available. All EMI shielding gasket products are produced under a quality system certified to ISO 9001:2015 by TUV Rheinland North America. Learn more about these products, standards and considerations for making your gasket selection, their beneficial applications, and how the Vanguard team can help support your operation.

EMI/RFI Shielding Gasket Overview

EMI shielding gaskets are designed to protect electronic equipment from harmful electromagnetic interference (EMI) and radio frequency interference (RFI). By creating a conductive path along the seams and other openings in an electronic enclosure, these gaskets establish smooth current flow and prevent destructive radiation from interfering with performance by completing a Faraday cage around the electronics.

EMI/RFI disturbances can destroy or disrupt electrical circuits, making EMI/RFI shielding gaskets a necessary component for a wide range of electrical equipment. There are many types of EMI/RFI shielding gaskets on the market, and they can be made from many materials, including plastic, foam, metals, and elastomers. It’s important to understand the various types so that you can select the appropriate shielding solution for your application.

About EMI Shielding Gasket Standards

The Vanguard team supplies EMI shielding gaskets to meet multiple industry standards and ensure you have the proper, compliant product for your project.

Key Standards for EMI Shielding Gaskets

Some of the standards and ratings related to EMI shielding gaskets include:

- MIL-DTL-83528. This military standard provides performance standards for electrically conductive elastomeric shielding gaskets. To comply with this standard, a gasket must have the appropriate base elastomer, filler material, durometer, thermal range, and shielding effectiveness against plane waves. At Vanguard, we offer MIL-DTL-83528 AQL-listed EMI/RFI shielding gaskets to fulfill Mil-Spec requirements along with our dual elastomer Ultra-Vanshield EMI shielding gaskets, which offer significant improvements on mechanical and cost properties while still meeting the basic electrical performance standard of MIL-DTL-83528.

- National Electrical Manufacturers Association (NEMA) ratings. These standardized ratings mainly target environmental sealing capabilities and the conditions in which it’s acceptable to use electrical enclosures. However, since our Ultra-Vanshield EMI shielding gaskets also perform the necessary environmental sealing, they are often used in NEMA-rated enclosures that have reached as high as NEMA 4/4X.

- Ingress Protection (IP) ratings. IP ratings define the level of particulate and water ingress an enclosure provides. Dual-function Ultra-Vanshield EMI shielding gaskets help our customers achieve high-level IP ratings, in some cases as high as IP67, all while providing superior EMI shielding.

- UL 50/UL 50E/UL 508: This standard applies to enclosures for electrical equipment intended to be installed and used in non-hazardous locations. It’s applicable to electrical equipment enclosures for indoor (Types 1, 2, 5, 12, 12K, and 13) and indoor/outdoor applications (Types 3, 3R, 3S, 3X, 3RX, 3SX, 4, 4X, 6, and 6P). This standard covers the construction and performance requirements for enclosures to provide a degree of protection to personnel against incidental contact with the enclosed equipment. This standard also covers additional environmental construction and performance requirements for enclosures. Our Ultra-Vanshield EMI shielding gaskets are listed by UL for use within this standard (UL File Number MH48850).

Other Considerations for EMI Gasket Shielding

Some additional factors that might impact your EMI shielding gasket choice include:

- Shielding effectiveness. This measure indicates a product’s capacity for electromagnetic wave attenuation.

- Frequency range. In order to determine the appropriate EMI gasket materials, it is important to define the frequency range over which an enclosure is expected to perform.

- Temperature range. This range denotes the thermal operating conditions over which the gasket is intended to perform.

- Material compatibility. Checking that a gasket’s material construction is compatible with the materials used in your system enclosure or equipment will help ensure proper gasket performance. Also, conversion coatings and/or painting systems are factors for consideration.

- Environmental factors. Moisture, chemical, and salt fog exposure are key aspects in determining the appropriate EMI shielding gaskets.

- Compression set. To determine whether a gasket will hold its shape or deform when exposed to compression force, you should be aware of its compression set.

- Available compression/deflection forces. It is important to determine the enclosure’s ability to compress the sealing material.

Industries We Serve at EMI Shielding Gaskets

To support our clients’ varied needs, Vanguard supplies standard and custom EMI shielding gaskets to diverse markets.

Key Industries

The primary markets our gasket solutions serve are:

- Aerospace and defense. These sectors frequently use EMI gaskets to prevent electromagnetic frequencies from damaging or interrupting sensitive aviation and military devices and systems.

- Automotive. Our gaskets can also protect against EMI in automotive components like electronic control units (ECUs), promoting equipment safety and optimal performance.

- Medical. Healthcare devices for general to critical care applications rely on EMI gaskets to support dependably safe functionality.

- Telecommunications. Shielding gaskets prevent EMI and the resulting signal quality degradation in different types of telecommunications equipment.

- Computers and electronics. Consumer electronics, computer systems, and servers often require EMI shielding gaskets to safeguard their various sensitive parts.

- Industrial automation. Machinery and control systems within the industrial sector use these gaskets to prevent the damage that would otherwise result from electromagnetic noise.

Other Industries

We also provide products for applications in industries such as:

- Marine. Many marine vessels have advanced electronic systems that could experience EMI, requiring sufficient shielding.

- Rail. The railway industry uses EMI shielding gaskets to protect control systems and electronic signals.

- Energy. Power systems frequently rely on shielding gaskets within their energy distribution and generation equipment.

EMI Shielding Gaskets From Vanguard

If your equipment is at risk of damage or malfunction from electromagnetic or radio frequency interference, reliable EMI shielding gaskets can provide sufficient protection, minimizing maintenance requirements, improving performance, and increasing your components’ lifespan. Vanguard offers several types of EMI shielding gaskets with custom options available to address the unique requirements of your application, giving you tailored solutions for your electronic components and systems.

Advantages

Ultra-Vanshield Dual Elastomer Shielding Gaskets Provide the Following Advantages Over Traditional EMI Gaskets with Conductive Particle Throughout Cross Section:

- Resilient inner core remains free of metal fillers

- Optimum compression and aging properties

- Silver conductive material is only present in outer thin membrane

- Excellent conductive properties

- Thin silver layer permits reduction in costly silver content

- Attenuation performance is not degraded under full compression

- Very low compression force

- Manufacturing flexibility

- Easy termination

- Single piece weather and EMI seal

- Extended galvanic protection

- NEMA, IP, wind driven rain, and immersion sealing protection

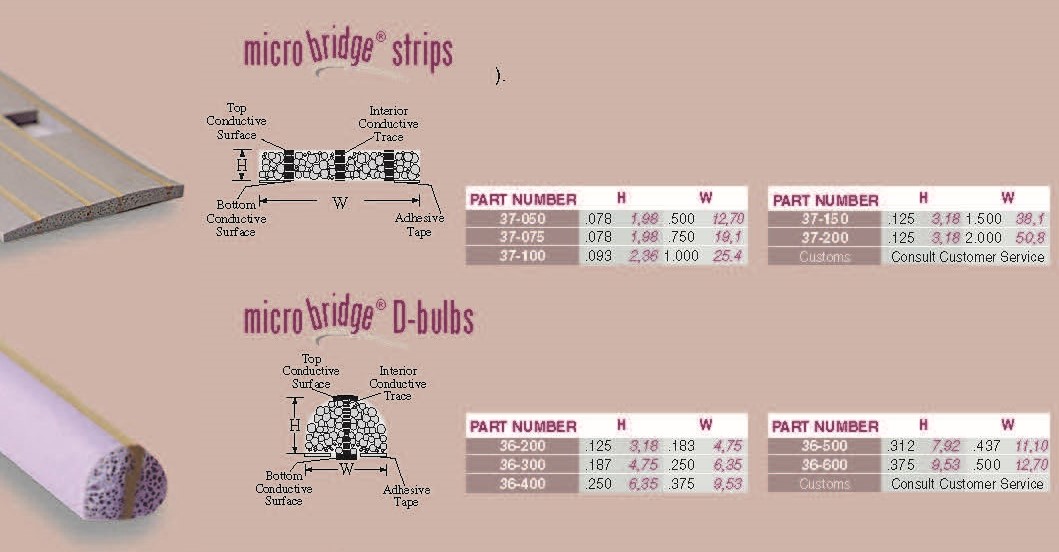

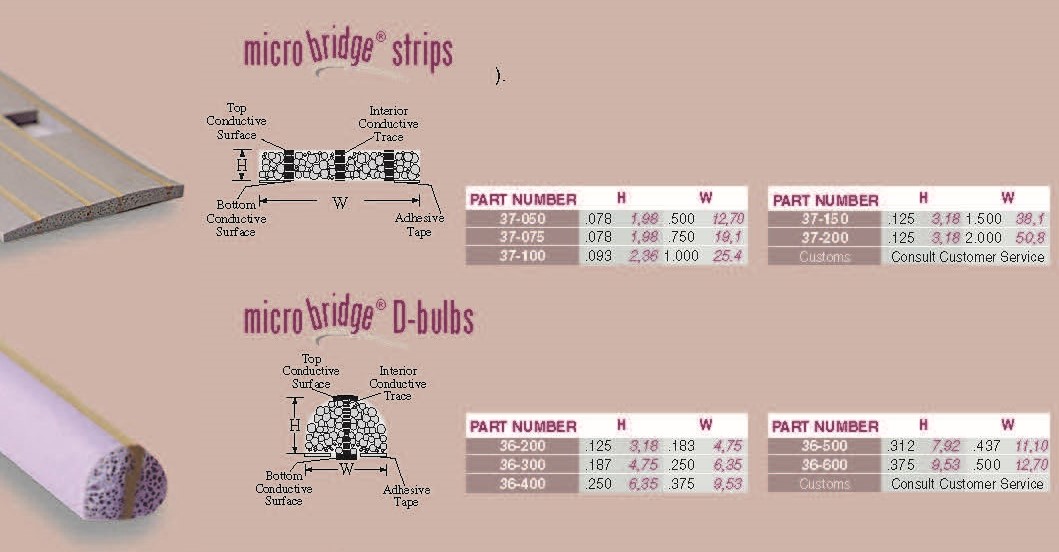

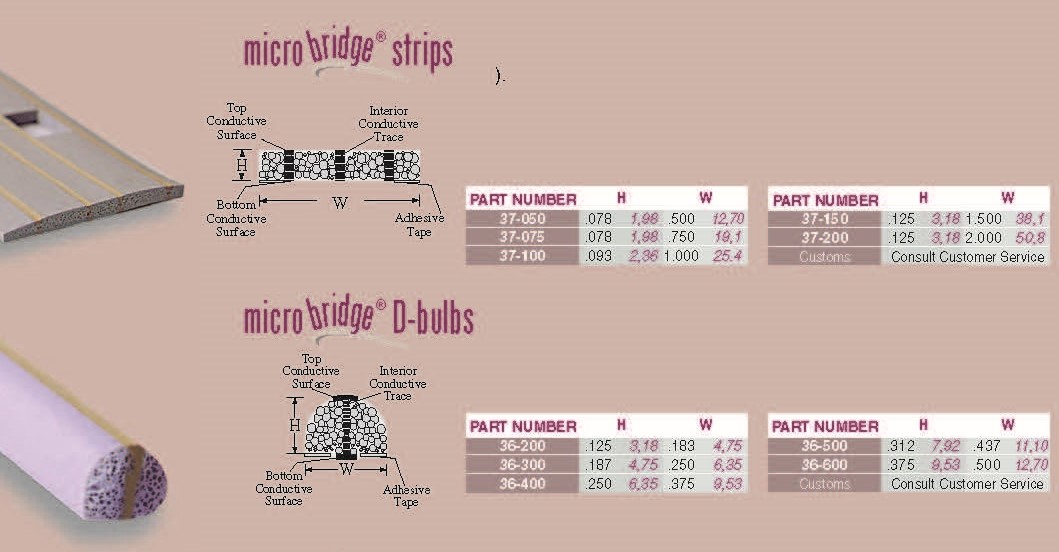

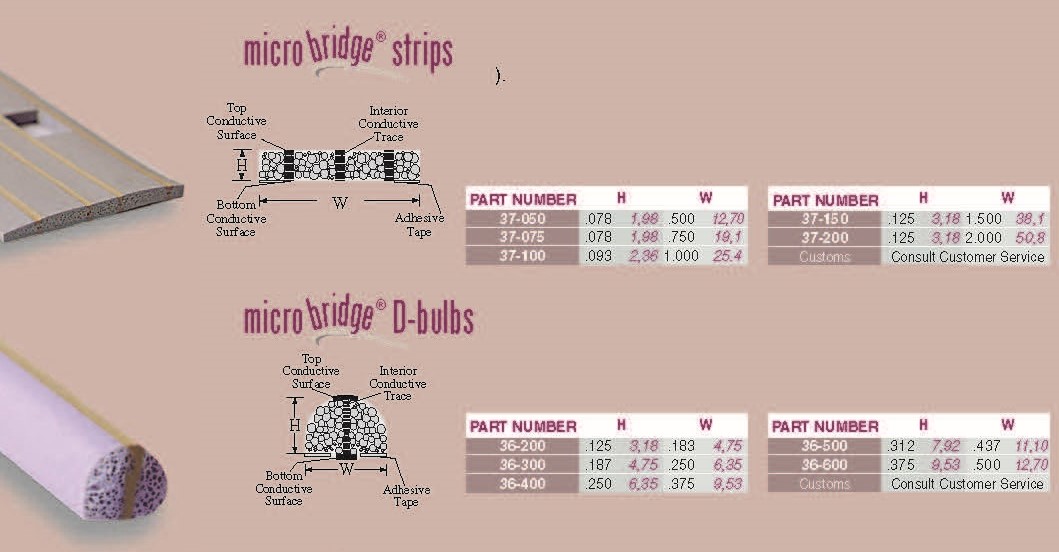

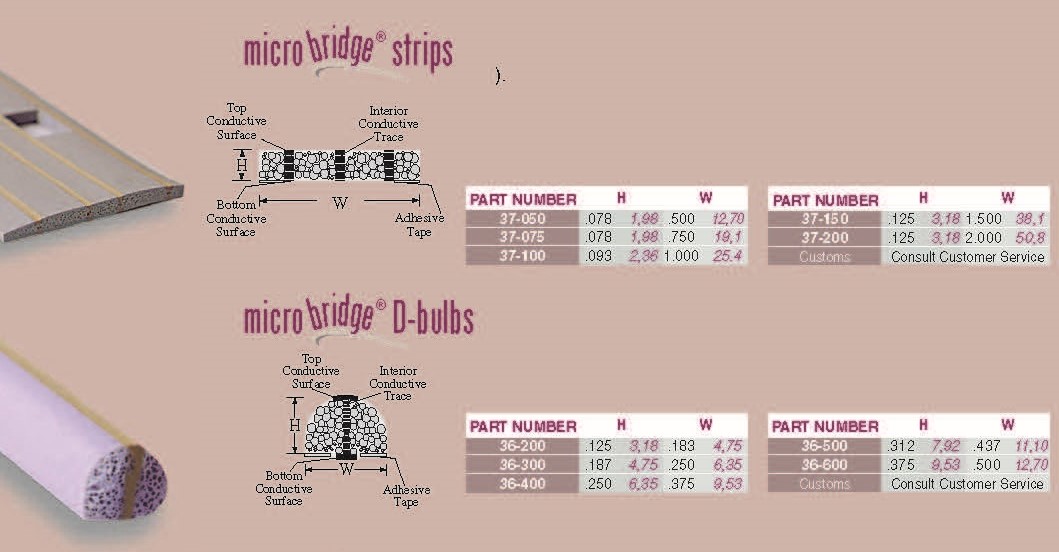

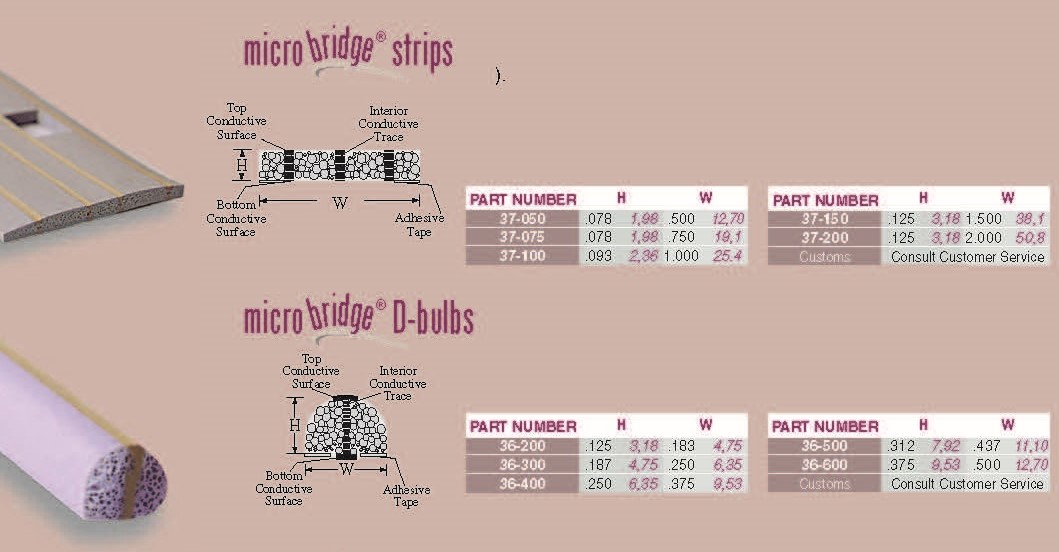

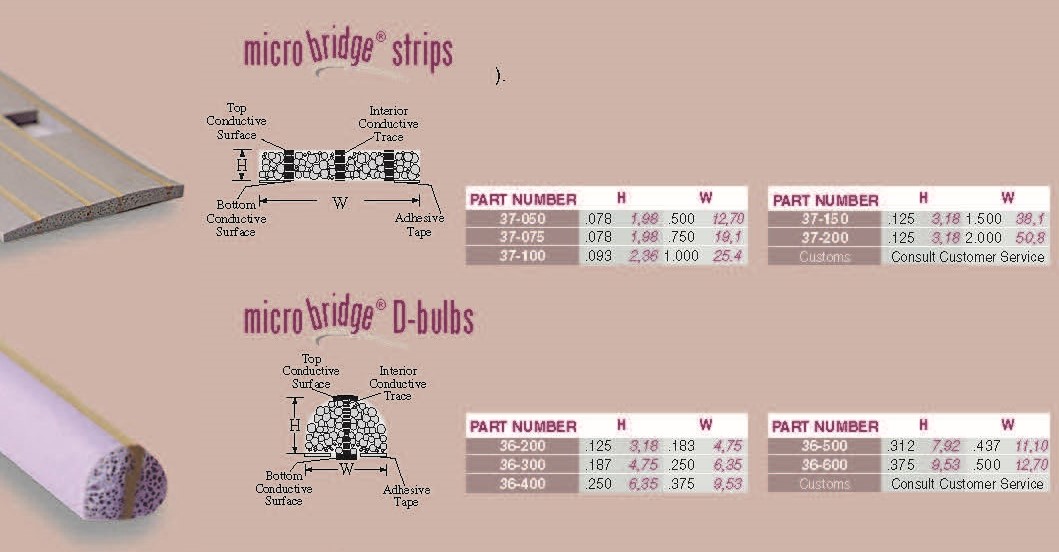

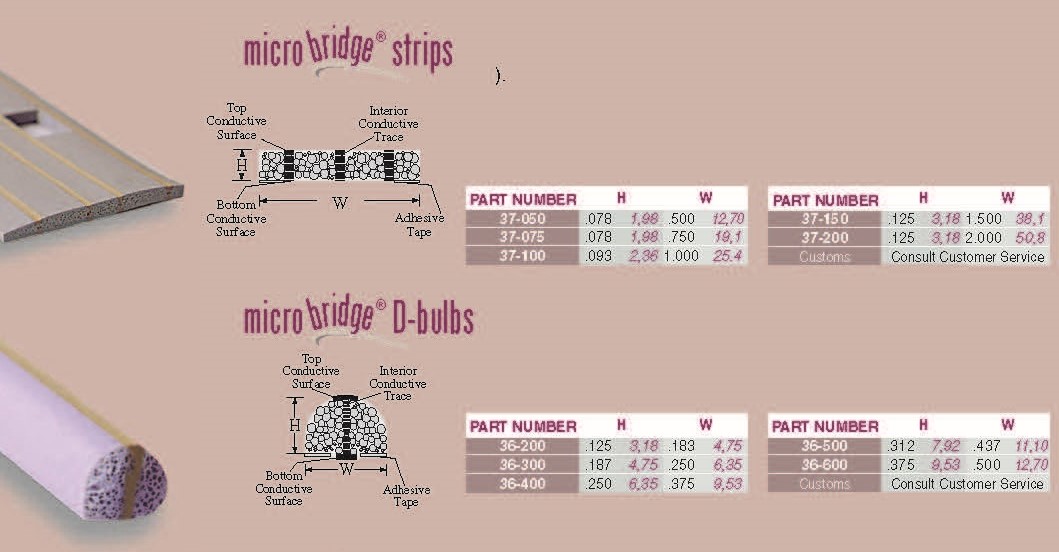

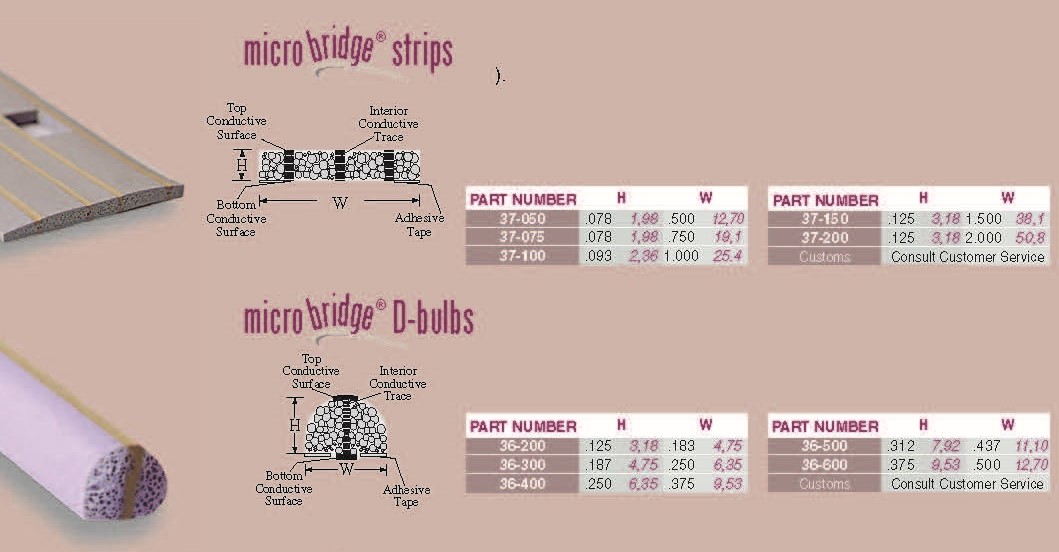

Microbridge™

(US Patent # 6,410,846B1 and 6,613,976B1, other patents pending)

- Same advantages as Ultra-Vanshield™

- Offers moisture seal on both sides of conductive portion for extended galvanic protection

- Further reduces silver content for better cost performance

Comparison of Ultra-Vanshield and Microbridge vs. Traditional EMI Shielding Gaskets

Versus Mesh, Ultra-Vanshield, and Microbridge has:

- Lower compression force

- Lower percentage of compression needed

- Environmental sealing higher shielding level

- Self-terminating

Versus Traditional Filled Conductive Elastomers, Ultra-Vanshield, and Microbridge has:

- Lower compression force

- Lower percentage of compression needed

- Environmental and galvanic sealing

- Comparable shielding level

- Improved compression set, tear, and crack resistance

- Better aging

Versus Spring Finger Gaskets, Ultra-Vanshield, and Microbridge has:

- Lower compression force

- Lower percentage of compression needed

- Weather sealing

- Comparable shielding level

- Easier to work with

- Won’t cut hands

- Can cut with scissors

- No maintenance necessary

Versus Fabric Over Foam, Ultra-Vanshield, and Microbridge has:

- Low compression set

- Broader temperature range

- Higher level of shielding

- Weather sealing

We specialize in applications assistance to identify alternative production approaches to save cost period.

Contact us today to learn more about our shielding gaskets and other products, or request a video consultation to speak with one of our application engineers.