Food grade silicone is a long-lasting, durable material that serves as a healthier, more inert alternative to plastics for use in food and beverage applications. The lack of plasticizers in silicone allows for far less leaching of BPA and other harmful chemicals into food and liquids, while also preventing taste and odors from being imparted to the food or beverage it contacts. Silicone is resilient, nonporous, and has a broad temperature range making it an ideal food storage and transport solution to combat single-use plastics.

Vanguard manufactures food grade silicone using highly precise, cost-effective processes under a quality management system certified to ISO 9001:2015 by TUV Rheinland North America. We use our in-house operations and custom compound formulations to create silicone products, making us a one-stop shop for food grade silicone extrusions, silicone tubing, and molded products.

Applications of Food-Grade Silicone Tubing

Food-grade silicone tubing is highly versatile, with applications that go beyond the food and beverage sector. While being safe for direct contact with consumable materials, the tubing’s durability, flexibility, and resistance capabilities lend it to applications in markets like healthcare and pharmaceuticals, as well.

Food and Beverage Industry

In the food and beverage sector, food-grade silicone tubing is perfect for handling and transporting food and beverage ingredients, products, and byproducts as it won’t impact their taste or impart odors. The tubing is safe for alcoholic beverages such as beer and wine, dairy products like milk, water, sauces, juices, and more. It’s also a common tubing option for commercial beverage dispensers.

The material inhibits food particle adhesion for increased cleanliness, helping protect product integrity. Also, as discussed, such tubing is effective at reducing a food and beverage operation’s reliance on single-use plastic materials.

Medical and Pharmaceutical Industry

Specifically engineered to meet rigorous cleanliness and hygiene standards, food-grade silicone tubing is essential for a variety of medical applications. In medical devices, the tubing can deliver gases and liquids to respirators or infusion pumps, whereas laboratory equipment might use silicone tubing to facilitate examination and research projects. In the pharmaceutical industry, silicone tubing is good for handling or transferring products and medicinal ingredients.

Whatever the application, food-grade silicone tubing is well-suited to the medical and pharmaceutical markets for its non-toxicity, chemical inertness, biocompatibility, and ability to withstand frequent sterilizations without breaking down. Tubing of this material is even resistant to bacterial growth.

High-Temperature Food-Grade Silicone Tubing

High-temperature food-grade silicone tubing offers superior performance under harsh conditions. Designed specifically for handling hot fluids, this flexible tubing can withstand temperatures of up to 500°F (260°C). In addition to its high food-grade silicone temperature range, it can also handle the cold, resisting temperatures as low as -100°F (-73°C). The tubing is resistant to aging and general wear as well, and it’s chemically inert and non-toxic. Like standard food-grade silicone tubing, it doesn’t introduce a taste or smell to the substances it transports.

Choosing the Right Silicone Tubing

Selecting the right high-temperature silicone tubing for your unique application helps ensure optimal performance and safety. First, verify that the tubing complies with 21CFR177.2600, the minimum FDA requirements for quality and safety to be considered a food-grade product. Also, it’s important to consider the intended application for your silicone tubing. It should be compatible with whatever materials or chemicals it will come into contact with to prevent degradation, and the tubing should also be capable of withstanding exposure to your project’s highest and lowest temperatures. As for dimensions, be sure to choose the ideal wall thickness, inner diameter (ID), and outer diameter (OD) to suit your application and its vacuum or pressure needs.

NSF 51 Food-Grade Silicone Tubing

The National Sanitation Foundation (NSF) has a certification standard in place, NSF 51, to help guarantee food and beverage product quality and safety. NSF 51-compliant tubing must first go through rigorous third-party testing before it can become certified. To meet NSF 51 standards, food-grade silicone tubing must offer sufficient:

- Physical Characteristics: NSF 51-certified tubing must feature good elongation and tensile strength to be considered safe for food processing and handling applications.

- Chemical and Temperature Resistance: Similarly, the tubing must be able to maintain its integrity and not degrade when exposed to the myriad chemicals and extreme temperatures food and beverage operations typically involve.

- Protection Against Extractables: Tubing won’t be considered safe per the NSF 51 standard if it releases harmful chemicals or other substances into any product passing through it.

Benefits of Using NSF 51 Food-Grade Silicone Tubing

NSF 51-certified food-grade silicone tubing specifically is advantageous for being a high-quality, FDA-compliant choice. Choosing to use this tubing gives you the peace of mind that it’s safe for consumable goods and will offer reliable performance. It will better protect the public against dangerous product contamination, help you build a reputation amongst consumers for dependable quality, and enable you to avoid costly fines.

Benefits of Food-Grade Silicone Tubing

Food grade silicone is a convenient material for constructing tough and durable food grade components. Some of the specific benefits of choosing food grade silicone over other plastics include:

- Damage Resistance: Food grade silicone can withstand extreme temperatures without damage and degradation.

- Durable: Food grade silicone won’t harden, peel, crack, dry out, crumble, rot, or become brittle over time.

- Tolerates High and Low Temperatures: Food grade silicone can withstand temperatures ranging from -103°F to 450°F.

- NSF-51 Certification: The NSF-51 certification establishes the requirements for third-party testing and ensures plastic products are safe for food use.

- Non-toxic and Odorless: The material is odorless and contains no BPA, lead, latex, or phthalates.

- Environmentally Friendly: Food grade silicone is considered non-hazardous waste.

Capabilities and Ranges of Food-Grade Silicone Products

Elastomeric Molding

- Single, Coextrusion, and Tri-Extrusion capability

- Multi-Lumen Extrusion

- Multiple Durometer/Hardness

- Multiple Material/Color Extrusion

- Insert Extrusion

- 0.010 inch to 3 inch Plus

- Custom Formulation for Mechanical Properties, Chemical Resistance, and Temperature Resistance; and Color Matching

- Cutting from 0.010” Thick to Unlimited

- Bonding

- O-Ring Fabrication

- Thin Walled

- Special Put-Ups

- Special Packaging

Materials for Food-Grade Silicone Products

There are many varieties of elastomers used for gaskets, seals, and tubing in the food prep industry that can be formulated to comply to FDA food contact requirements, including:

- Nitrile: Nitrile is used for a wide range of food industry applications with temperatures ranging from -20°F to 150°F as well as applications that employ grease and oils.

- Neoprene: Neoprene is resistant to abrasion and oils.

- Food Grade Silicone: FDA silicone can handle low and high temperatures from -100°F to 450°F. It stays flexible and durable in any environment and can be formulated to resist damage from fats, oils, and other food chemicals.

- EPDM: Food grade EPDM can be used for gaskets and surfaces in any food prep environment.

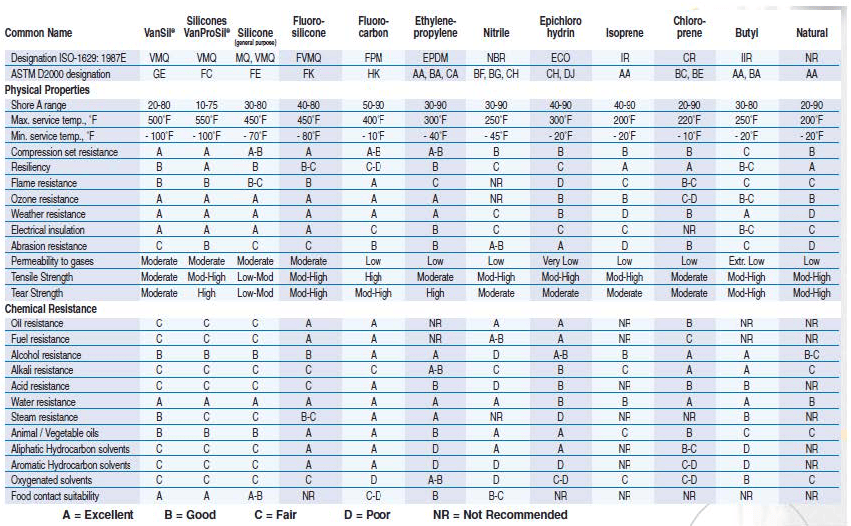

Material Application/Compatibility Guidelines

Vanguard utilizes various grades and varieties of silicone to manufacture custom food-grade products in an extensive range of applications, industries and specific environments. If you are not sure which material is best for your application, please contact one of our application specialists today to assist you.

Food-Grade Silicone Tubing From Vanguard Products

At Vanguard Products Corporation, we handle food grade silicone manufacturing and engineering projects from start to finish. We use specially selected raw products to produce FDA-compliant gaskets and other food processing components. For over 50 years, our team has provided high-precision, high-quality, domestic products. For more information, contact us or request a quote today.

Silicone

Food Grade

- Consistent With FDA Regulation 21CFR177.2600 For Food Contact

- NSF-51 Certified

- Animal Fat And Chemical Resistant

- 3A

- High Temperature

- Closed Cell Sponge

- Dense

- 5-90 Shore A Durometer